Methan Tube

Behind the idea

Biological Care is a market leader in the field of renewable energies for what concerns consultancy and strategic vision. In particular, we are able to guide every agri-food company in the management of their waste products. Our activity is focused at researching and buying biomasses on international markets in order to create customized, high potential energy mixes to help our clients to build a biogas plant and manage it from A to Z.

Over the time we sold products and made on-site assistance to hundreds of biogas plants. We experienced a wide range of different performances related to new substrates added to biogas plants in order to reach the maximum efficiency. Different bacteria and chemical conditions, different technologies leaded us to create an instrument able to quickly understand how the feedstock can perform according to the bacteria and biogas condition of the costumer.

The “right” product carrying good nutrients can balance the feeding mix and increase the biogas performances well above the biogas potential of the product just added.

Giving the right nutrient to the plant is possible to better exploit the whole inlet feedstock. Adding the elements which is in short supply can quickly increase the performances and help the biogas plant biological condition.

We used the Methan tube kits for years before to decide to put the instrument on the market. The chance to see how your bacteria can digest a new product in few days is the key point to optimize your biogas and choose the right product.

Furthermore, thanks to the residual potential, you can really understand how your digesters are converting the feedstock and what is the leftover from every stage of the plant. Adding substrate at the right point in the right digestor can have a huge impact on performance, electricity self-consumption and intoxications.

Thanks to our research and experiences, the instrument has the right features for the biogas needs. Simple to use tool but at the same time precise and useful to evaluate new opportunities on the market and calibrate the digestors.

The methan tube is a great success and the costumer can finally make a self-diagnosis without be biologist. Methan tube gives voice to your biogas plants.

Brief description

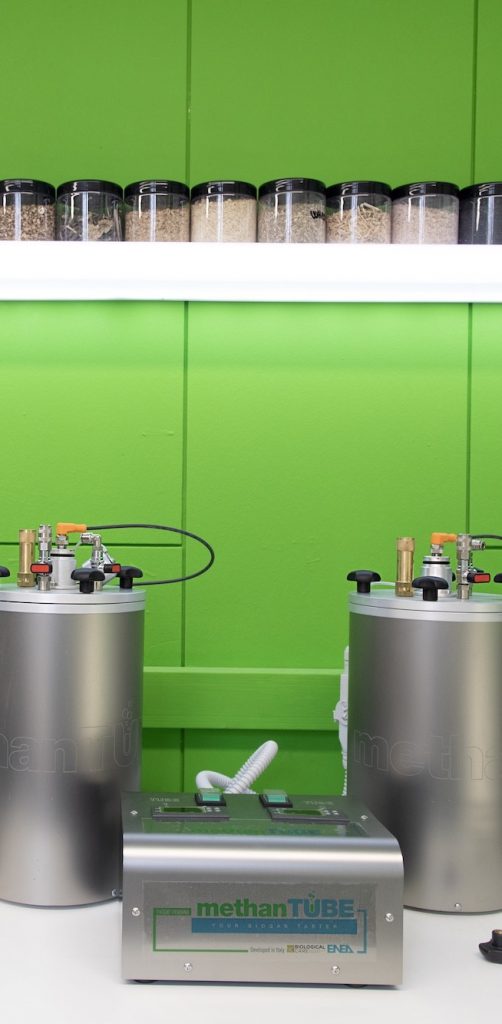

Methan Tube® is a tool that measures the amount of biogas produced by barometric method, therefore based on detecting the pressure produced by the biogas developed inside the tool. The device is designed to detect and process the results in a completely automatic manner, reducing the cost and the time required for the analysis. The tool can be summarized in two main parts: hardware and software.

Methan Tube® is an innovative, portable system that measures directly on site the true methanation of organic substances. Methan Tube® analyzes any biomass you want to use and simulates your system’s real biogas plant conditions, setting your digester temperature and using your own digestate.

Methan Tube® enables you to test new diets both in terms of quality and quantity, leading the operator to avoid any waste.

Evaluations of biogas production are based on the pressure of the biogas produced inside the digesters. Afterwards, this data is processed by the software that turn tests into graphics and online curves of biogas production.

Methan Tube® has an online website, for managing fermentation tests and consulting previous ones, and an online database with over 400 substrates already analyzed with Methan Tube®.

Methan Tube® consists of a control panel, for temperature setup and cloud data collection, and 2 or 4 reactors connected at the panel. The 4-reactors version allows you to conduct 3 different tests at the same time, instead of the 2-reactors version that allows one test per time.

The control panel is the same for both versions: this allows you to upgrade the MT02 version in MT04 by just adding another pair of digesters anytime.

With our Methan Tube®, with an efficiency test on the output digestate you have a fast and clear answer on the issue:

More feeding material means less retention time inside the plant. The output material is still productive, and you are losing gas outside the digester.

The Methan Tube® gives you the chance to quickly understand the gas potential from your digestate and save money and time.

About Methantube

The Methan Tube® device is an easy-to-use analytical tool designed to estimate the potential production of biogas.

Methan Tube® exploits the innovative combination of an ad hoc developed software and Laboratory scale heated digesters, where the fermentation takes place, the gas production is detected, and data stored online. The instrument uses delta pressure combination between the digesters to investigate the biogas potential from the added feedstock inoculated.

The conventional tools are very complex costly and require a skilled operator. In other words, the tolls are limited to a laboratory environment.

The standard biomass analysis in labs is carried out on standardized biological digestate. Therefore, with different chemical-physical and biological characteristics compared to the fermentative material in your biogas plant. As a result, the assessment of estimated production carried out in a laboratory is inaccurate since it is not representative of the actual conditions of the biological process to which the biomass is subjected.

On the contrary, Methan Tube® is meant to be used by the plant operator, with on-site collected biological material, and thanks to the software is able to provide both real-time and forecast results.

The tool management and the consulting of the results are possible via an ad hoc developed web interface. In this way, each user can consult the results even when away from the Instrument, as the continuous presence of an operator is not required.

Each user has a personal access to the website, where he can carry out new tests, show history of previous tests and consult those underway.

Methan Tube® is the unique instrument able to understand the real biogas potential of new products related to your biogas bacteria consortium inside the biogas plant. You will be able to define the commercial value of new products based on the biogas produced with your bacteria. The device can investigate the efficiency of your plant, the residual biogas production from your output digestate. Finally, you will have the chance to get the real residual biogas production data from your plant and evaluate the performances without complex analysis and index. Using the MT, you will temporary extend the hydraulic retention time of your plant inside the small digester and clearly understand how much gas you still can produce from your digestate.

Operating Principles

The scenario

Let’s say that you have the chance to get a new product for your plant for example tomato by-product, very cheap and not so performing but… why not… it almost free….

After one week using this new product you experience a small reduction in performances, you make some analysis on the new product, maybe some inhibition test… but everything is good. In the meanwhile, the performance keeps going down.

At the second week the performance is worsening, and you have no idea how to solve until you decide to remove the new feedstock from your feeding schedule.

After two days you get the performance back at good level.…. so for sure the new product is the reason (maybe some inhibition not detected in the analysis..). It’s a pity, a very cheap product very close to my plant….

What happened in the reality?

The new product is performing well and there is no problems and inhibition. The biogas plant faced an increase of inlet mass and a decrease of retention time inside the digesters so the biogas potential from the new feedstock is lost outside the digesters and not properly collected.

Solution

So yes the product can be used keeping in consideration the residual gas potential on the output digestate.

In order to keep the Retention time at standard level, you can perform a solid liquid separation and use just the solid material.